HEADLINE: “Dick Storm's Thoughts on Energy, Education, Economic Prosperity & Environmental Blog”

The Reality of Building 125 GW of New Coal Plant Generation Capacity Then and Now

Dick Storm's Thoughts on Energy, Education, Economic Prosperity & Environmental Blog

The Reality of Building 125 GW of New Coal Plant Generation Capacity Then and Now

May 7, 2025 5:41 pm

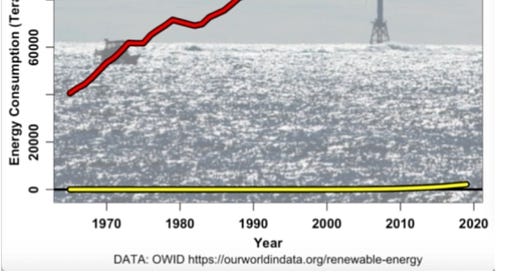

It has been forecasted that the U.S. needs about 125 GW of new electricity generation capacity by 2030 and about 600 GW of new generation capacity by 2050. The combined maximum manufacturing of new nuclear, new wind and new solar cannot provide this growth in time. Previously written here, here and here. The Our World in Data graph showing worldwide capacity of total primary energy by sources shows the futility of expecting the new Demand for energy to be supplied from wind and solar.

The graph above illustrates the dismal contribution of wind and solar to the total Primary Energy needs of the world. Bjorn Lomborg (and others) has written numerous articles that document the poor capacity factor, high cost and unreliability of wind and solar after decades of spending billions.

The answer to providing the needed Primary Energy for electricity generation over the next twenty five years is to build more dispatchable electricity generation capacity from new natural gas, nuclear and coal plants. We need to build lots of new gas, nuclear and coal plants. Easy to write, harder to accomplish. That is the purpose of this article, to try to quantify the colossal design, manufacturing and construction supply-chain effort that needs to be accomplished on a fast-track basis.

New Generation Capacity Manufacturing Supply-Chain

The gas turbine supply-chain limitation was covered in my previous article here and by POWER Magazine here.Nuclear is the fuel that provides the largest carbon free capacity today and it is likely to be the fuel of choice in the future. However, building 125 GW of new electricity generation capacity by 2035 or so could with a Herculean effort be accomplished with new coal plant construction. This is about the same as the electricity generation capacity that has been shut down since 2010. The previous article discussed the 151 new coal plants that were planned in 2008 most of which were never built. Between now and 2035 we need to build the coal plants that were planned in 2008 and were never built.

The Coal Plant Supply-Chain That Was circa 1975-1980

In 1975 I was a project engineer for the startup and improvements for the 720 MW Roxboro Generating Station Unit #3. The superheater needed to be replaced with upgraded alloy due to design issues of temperature and steam distribution throughout the over 1500 individual flow circuits. The tubing material selected was 304H stainless steel. Over twenty miles of new tubing needed to be fabricated into 48 superheater assemblies, each comprised of 26 tube circuits about 120 feet long. The contract was signed about March of 1975 for delivery to site and installation in the fall outage the same year. The tubes had to be manufactured from stainless steel billets, drawn into tubing and the tubing bent, attached together into assemblies, stress relived in a furnace and welded together. The total superheater required dozens of truck loads for delivery from Chattanooga to Roxboro. The same project today would be possible but not in the same time frame. It will require more than a year or two to simply fabricate a superheater of this size and get it delivered. Much of the tubing and components would be sourced from Asia.

Remembering Combustion-Engineering

Let’s discuss Combustion-Engineering’s Chattanooga works in 1975. Here is an aerial picture of this magnificent facility.

The facility was over 88 acres under roof and included capabilities for manufacturing steel tubing, waterwalls, heavy walled headers, fabrication of tube assemblies as described above for the Roxboro superheater and also nuclear reactors and steam generators. I intentionally used the adjective magnificent to describe it. Here is a quote from my friend Tom who worked at C-E during this time period:

“I did a stint at CE in Chattanooga and still vividly recall the enormity of the manufacturing capability. For instance 15,000 ton press that could bend 12” thick steel Into a cylinder for a completed nuclear vessel weighing 700 tons.

A Gang drill setup to drill 1600 holes through a 26” Inconel tube sheet for nuclear PWR steam generators.

1000 ton crane to handle these fabrications and heat treat furnaces large enough to stress relieve them before shipment. What an experience to view and work with these marvels.”

The facility evolved and progressed over many years to become the pearl of manufacturing prowess that it was in 1975. Combustion-Engineering in these times was capable of producing steam generators that could power about 25,000 MW of electricity generation capacity each year. The business volume in 1977 dollars was about $1 Billion/year. The manufacturing volume was almost equal to the business profits of aftermarket maintenance and repairs. Being outstanding in design, manufacturing and services was a huge business for tens of thousands of employees. In 1978 Combustion-Engineering was # 125 on the Fortune 500 list of companies. Two competitors during this era with facilities similar to Combustion-Enegineering were Babcock & Wilcox and Foster-Wheeler. B&W was # 132 on Fortune’s list and Foster-Wheeler # 207.

Today Combustion Engineering and Foster-Wheeler U.S. shops are gone, B&W’s downsized but, thankfully, still in operation.

Today I discussed a replacement/repair of a high pressure header for a Utility coal steam generator in Texas. I was told the header is on emergency order and it will be on site this fall. The header is sourced from somewhere in Asia and welding of tube studs and completion of fabrication will be done in South Carolina. This is bout 24 weeks lead time for just one header. I described a 1350 MW steam generator in a previous article, here. Just to show a rough idea of the immensity of a large coal steam generator. The one described is the B&W Zimmer Plant, supercritical steam generator. In electricity generation capacity, it is nearly twice the size of Roxboro Unit #3.

How About Talent?

I was watching Mike Rowe on TV yesterday and he stated that today over 485,000 manufacturing jobs remain unfilled. Tens of thousands of highly skilled craftsmen such as the Boilermaker/Welders such as those shown below are needed. But, the training and education of the workforce is a topic for another day. Here is a recent WSJ article on building the craft workforce.

Building a new 1600 MW Coal Plant

One of the most recent coal plants built is the Prairie States Energy Center in southern Illinois. The plant construction is well documented by Bechtel and Prairie States. Here are some statistics to explain the immensity of the challenge of building a plant such as the Prairie States Energy Campus.

Now do the math. It will take about 78 new coal plants like Prairie States to produce 125,000 MW of electricity. Using the proportions of what it took about 13 years ago to build the Prairie States Energy campus would extrapolate to:

12,870,000 yards of concrete

3,276,000 tons of steel

210,600 construction workers

93,600 miles of electric cable, mostly copper

9,360 miles of piping

This does not include the engineers and designers to prepare the engineering drawings, the factory personnel such as those once employed at the C-E Chattanooga Works described above or Foster-Wheeler’s Mountaintop Pennsylvania facility. I estimate that over 250,000 new engineers, technicians, craftsmen and other factory workers will need to be trained and employed to accomplish this huge task. Unfortunately, many of the trained and experienced engineers needed are like me and many of my friends, who are now retired. The next generation has a huge job to rebuild the supply-chain.

Conclusions

Needed is 600 GW of new reliable, affordable, dispatchable and preferably, U.S. made generation capacity. Satisfying this demand for new capacity will require more new gas, new coal and new nuclear plants to be built. As discussed above, the new gas turbine manufacturing capacity is at it’s limits and optimistically, about half of the needed 600 GW by 2050 can be provided by G-E, Mitsubishi, Siemens and a few others.

Nuclear today provides about 100 GW of electricity generation. Most of the nuclear plants providing this power were built over 40 years ago. It took over 30 years to build the first 100 GW of nuclear generation and yes, we should proceed full speed ahead on doing so again. All things considered, including manufacturing facilities, talent, forgings, high grade nuclear quality steel production and site construction challenges, doubling the 100 GW of existing nuclear capacity may take another 30 years. America misses both the manufacturing facilities such as C-E Chattanooga and others and the 125 GW of coal plant capacity that also has disappeared.

The solution, in my view, is build more coal plants and build them now. It will be difficult to ramp up the supply-chain, but we should begin ASAP. Building plants like Prairie States takes years. At best, about four years from the start of engineering to the first connection to the Grid and then it usually takes months of debugging and fine tuning to reach the full potential of a new plant.

The Roxboro Generating Station has been mentioned by me in many of my articles and talks. Why? Because I was employed at Roxboro as a field service engineer, senior startup engineer, operations superintendent, maintenance contractor and consultant over a fifty year career. I know (or at least remember it) Roxboro plant very well. A side note, Mr. Mendall Long, one of the Greatest Generation and past Manager of Fossil Plant Engineering told me late in his life, “Lad, you are the only guy I know that made a full career out of working on only three boilers” Mr. Long was referring to the Riley Boilers at Sutton and Roxboro Plants that I did indeed work on (amongst others) over a forty year period during his life-time. We miss extraordinary and courageous engineer/managers like Mr. Long.

Roxboro has a capacity of 2,462 MW. I use this plant as an example of the 125 GW’s of new power needed. It will take 50 new plants like Roxboro to produce 125,000 MW’s of coal plant capacity. I described the superheater replacement for Unit #3 above. That is only one unit. Roxboro has four operating units. The Prairie States Energy Campus is a better example because it is newer.

POWER Magazine wrote in October 2013: “The 1,600-MW Prairie State Energy Campus uses the latest coal technology to burn Illinois coal from the Lively Grove mine, located adjacent to the plant. In planning since 2001, the second unit of the two-unit, $4.93 billion plant entered commercial service in November 2012, thus completing the largest coal-fired plant built in the U.S. in 30 years.

The Prairie State Energy Campus (PSEC) is likely the last of the multi-unit coal-fired power plants that will be built in the U.S. in the foreseeable future. The most recently commissioned coal plants (SWEPCO’s 600-MW John W. Turk, Jr. and Duke Energy’s 825-MW Cliffside Unit 6) are single-unit plants with no firm plans for future expansion. The last two-unit coal-fired plants completed as a single project were Luminant’s Oak Grove power plant (2 x 800 MW) and We Energies’ Elm Road plant (2 x 615), both completed in 2010, but that’s where the similarity ends.”

As mentioned above, America should build 78 new plants similar to the Prairie States Energy Campus. We should begin now as the electricity generation crisis is real, not imagined. In 2008 over 150 new coal plants were planned. Most of these were cancelled. That was a mistake that needs to be corrected.

Dick Storm , May 7, 2025

BOTTOWLINE: We should begin now as the electricity generation crisis is real, not imagined. In 2008 over 150 new coal plants were planned. Most of these were cancelled. That was a mistake that needs to be corrected.

Thank you Stephen Heins for publishing this. The numbers are sobering and the Spain Blackouts only the beginning if our policymakers do not wake up. I appreciate your help in getting the true facts out to the public. I have believed for a long time that our electricity and energy policies are run by SWAMP Bureaucrats while only about 3% of the public understand energy and electricity generation. Even well educated people have no idea of what is behind the electric outlet in their home or business....